Deutz MWM models

| Deutz MWM models | ||

| BF6M1015M | BF6M1015MC | BF8M1015MC |

| TCD 2015M V6 | TCD 2015M V8 | |

| TBD616 V8 | TBD616 V12 | TBD616 V16 |

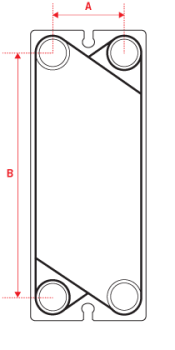

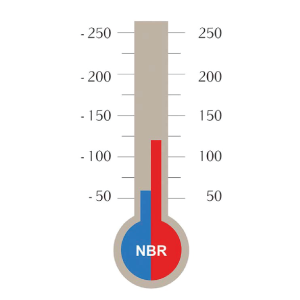

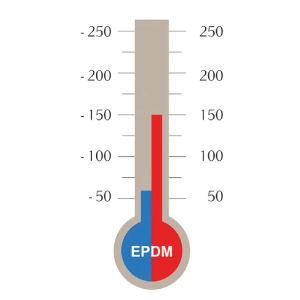

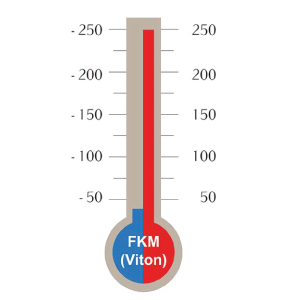

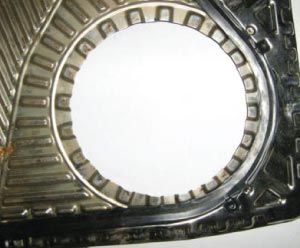

Gasket Selection.

| Deutz MWM models | ||

| BF6M1015M | BF6M1015MC | BF8M1015MC |

| TCD 2015M V6 | TCD 2015M V8 | |

| TBD616 V8 | TBD616 V12 | TBD616 V16 |

Selecting the wrong gasket can be a timely and costly mistake. Let our experienced THS sales team recommend the most durable and cost effective gasket material for your application by providing us with the pressure, temperature and process liquid details.

Buna (NBR/Nitrile), EPDM or Viton materials are the most common plate & frame heat exchanger gaskets depending on the operating application.

Clip - will usually have rubber tabs that are visible from the outside of the heat exchanger

Glue – no tabs and in most cases the brown glue is visible under the gasket; typically used in high pressure or high temperature applications

Ball - used in HVAC or FDA applications to allow for easy removal in the field

Double wall plate and frame heat exchangers (PHEs) are designed to prevent cross-contamination, making them essential for applications like potable water, food processing, and pharmaceuticals.

A common question is: Can double wall PHEs be chemically cleaned?

Yes, double wall PHEs can be effectively cleaned using chemical flushing or Clean-in-Place (CIP) methods, as confirmed by industry leaders like Heat Exchanger Ontario, ensuring efficiency and safety when performed by professionals.

What Are Double Wall PHEs?

Double wall PHEs feature two plates between fluid channels, providing a failsafe against leaks and cross-contamination, as noted by T.H. Industrial Solutions. This design ensures that if a plate develops a pinhole or crack, fluids remain separated, critical for potable water systems under municipal codes.

How Are Double Wall PHEs Chemically Cleaned?

Chemical cleaning methods for double wall PHEs include:

Effectiveness of Chemical Cleaning

Chemical cleaning is highly effective for double wall PHEs because it:

Limitations and Considerations

When to Chemically Clean Double Wall PHEs

Chemical cleaning is recommended every 5–6 years or when differential pressure reaches 7–10 psi, indicating fouling. It’s ideal for routine maintenance in potable water or food systems, ensuring compliance with safety codes.

Conclusion

Double wall PHEs can be chemically cleaned using CIP or chemical flushing, effectively removing fouling while maintaining their anti-contamination design. Industry leaders like T.H. Industrial Solutions offer expert services to ensure efficiency and safety.

Double wall plate and frame heat exchangers (HXs) are designed to prevent cross-contamination, making them critical for applications like potable water, food processing, and pharmaceuticals.

A common question is: Can double wall HXs be cleaned using high pressure water?

Yes, high-pressure water jetting is an effective method for cleaning double wall HXs, particularly for stubborn fouling. However, it requires careful execution to avoid damaging delicate components.

What Are Double Wall HXs?

Double wall HXs feature two plates between fluid channels, ensuring no mixing of fluids if a plate fails, as noted by T.H. Industrial Solutions. This design is vital for potable water systems under municipal codes, making regular cleaning essential to maintain performance and safety.

How Are Double Wall HXs Cleaned with High Pressure Water?

High-pressure water jetting, often at pressures up to 2,500 bar (36,000 psi), removes tough deposits like scale, marine growth, or debris from HX plates. The process typically involves:

Effectiveness of High-Pressure Water Cleaning

High-pressure water cleaning is effective for double wall HXs because it:

Limitations and Considerations

When to Use High-Pressure Water Cleaning

High-pressure water cleaning is ideal for double wall HXs with severe fouling, such as marine growth or hardened scale, where CIP or chemical flushing is insufficient. It’s common in industries like power generation or marine applications. For routine maintenance, CIP is often preferred to avoid disassembly.

Conclusion

Double wall HXs can be effectively cleaned with high-pressure water, particularly for tough deposits, but careful execution is needed to protect their anti-contamination design. Industry leaders like T.H. Industrial Solutions offer expert services to ensure efficiency and safety. Trust professionals to maintain your double wall HXs.

Plate and frame heat exchangers (PHEs) with 0.4mm thick plates are designed for high efficiency in applications like HVAC, food processing, and pharmaceuticals. However, their thin plates make servicing challenging.

A key concern is: What are the risks of servicing PHEs that have 0.4mm thick plates?

Servicing these PHEs, if not done carefully, can lead to plate damage, leaks, or reduced performance, as noted by experts like Alfa Laval and Heat Exchanger Ontario. Understanding these risks is critical for effective maintenance.

Why Are 0.4mm Thick Plates Challenging?

Thin plates (0.4mm) in PHEs, often made of stainless steel or titanium, maximize heat transfer but are delicate, increasing vulnerability during servicing. Improper handling or cleaning methods can compromise their integrity, especially in high-pressure or corrosive environments.

Key Risks of Servicing PHEs with 0.4mm Thick Plates

Mitigation Strategies

When to Service PHEs with 0.4mm Plates

Service every 5–6 years or when differential pressure reaches 7–10 psi, indicating fouling, per T.H. Industrial Solutions. Routine maintenance prevents severe fouling, reducing the need for aggressive cleaning methods that risk damage.

Conclusion

Servicing PHEs with 0.4mm thick plates carries risks like plate damage, corrosion, and gasket failure, but these can be mitigated with careful methods and expertise. Industry leaders like T.H. Industrial Solutions offer specialized services to safely maintain these delicate systems. Trust professionals to protect your PHEs and ensure optimal performance.

As a heat exchanger becomes fouled with dirt, debris or scale, often the modulating valve provides additional hot or cold liquid to help compensate for the loss of efficiency of the heat exchanger.

Over time the control valve will continue to open fully. Unfortunately, on the hottest or coldest days, even with the valve fully open the heat exchanger cannot meet the thermal transfer requirements and the situation becomes critical.

Monitoring just the operating temperature provides a false sense of security. Recording the difference in the outlet and inlet pressures provides a more accurate result of the amount of fouling.

Fouling equal to the thickness of a piece of paper represents a 20% loss of thermal efficiency. In addition, the energy cost for pumps increases since the pump must work harder to overcome the increased pressure resistance through the PHE

T.H. Industrial Solutions Inc. (THS) has been servicing industrial plate and frame heat exchangers as with shell and tube heat exchangers. Professionally solving process problems across Canada since 2009. THS head office is located in Pickering, Ontario with a 6,000 square foot service center in Hamilton, Ontario.

Today there are fewer qualified people in this industry that know the products and understand the applications. Utilizing hands on experience and knowledge that has been gained by our THS sales and service technicians for over the past 30 years, we will take the time to understand what you require and strive to provide a prompt, educated and accurate response at a competitive price.

Our Heat Exchanger Cleaning Services, along with heat exchanger gasket replacement systems, and knowledge of heat exchanger gasket materials make THS your Industrial Heat Exchanger Service Solution

1550 Bayly Street, Unit 15

Pickering, ON L1W 3W1

T 905 831-4963

76 Harlowe Road, Unit 4 - 7

Hamilton, ON L8W 3R6

T 905 318-0777

F 905-318-8422

1550 Bayly Street, Unit 15

Pickering, ON L1W 3W1

76 Harlowe Road, Unit 4 - 7

Hamilton, ON L8W 3R6