Plate & Frame

Heat Exchanger.

Advantages of a PHE

Small Footprint

Service Accessibility

Efficiency

Fluid Compatibility

Versatile Design

Expandable Design

Disdvantages of a PHE

-

ContaminationOver time plates will build up with scale and debris

-

ReplacementGaskets tend to leak overtime, typically after 10-15 years replacements are required depending on the application

-

ApplicationNot compatible for higher temperatures and pressures

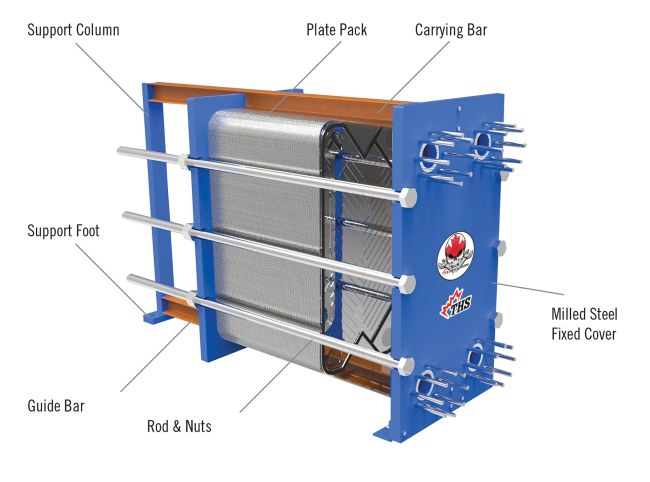

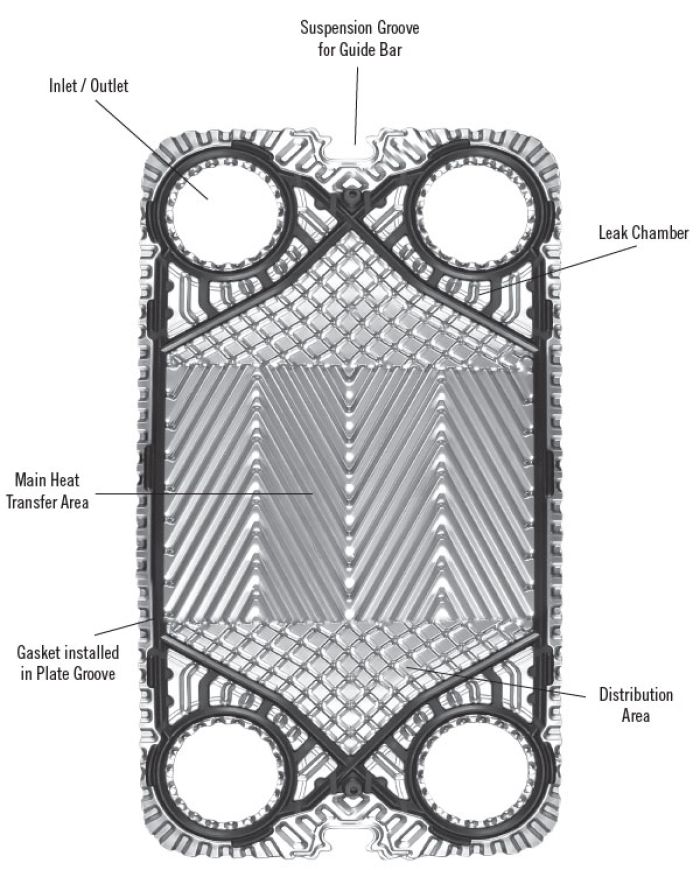

Main Components of a Plate

Applications

Food & Beverage

Sterilization

Evaporation

UHT Treatment

Reception Thermization

Wort Boiling

Industrial

Demineralization

Evaporation

Economizing

Heat Recovery

Quench Oil Cooling

Caustic Solution Heating

Energy

Geothermal

Quench Coolers

Lubrication Oil Cooling

Corrosive Fluid Heating/Cooling

Crude Oil Heating

Diesel Engine Cooling

Auxiliary Cooling

Chemical & Pharmaceutical

Glycol Cooling

Reactor Cooling

Extraction

Fermentation

Fragmentation

Methanation

Commercial HVAC

Swimming Pool Heating

Free Cooling

Cooling Tower Isolation

Heat Pump Systems

Heat Recovery

Thermal Storage Systems

Marine

Auxiliary Power Generation System

Jacket Water Cooling

Central Cooling

Seawater Isolation Exchanger

Engine Oil Cooling

Ventilation Coolers and Heaters

When Should A Plate & Frame Heat Exchanger Be Serviced?

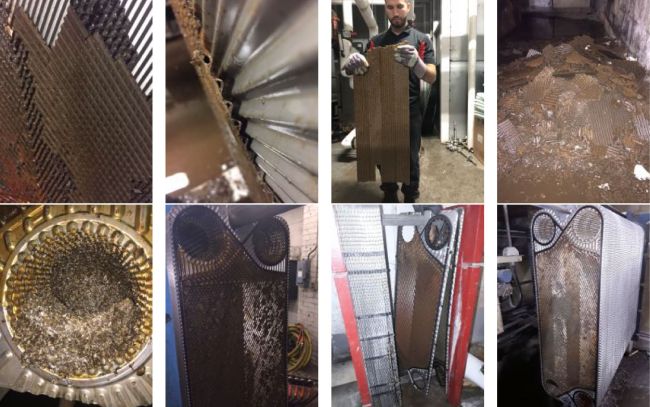

As a heat exchanger becomes fouled with dirt, debris or scale often the modulating valve provides additional hot or cold liquid to help compensate for the loss of efficiency of the heat exchanger.

Over time the control valve will continue to open fully. Unfortunately on the hottest or coldest days, even with the valve fully open the heat exchanger cannot meet the thermal transfer requirements and the situation becomes critical.

Monitoring just the operating temperature provides a false sense of security. Recording the difference in the outlet and inlet pressures provides a more accurate result of the amount of fouling.

Fouling equal to the thickness of a piece of paper represents a 20% loss of thermal efficiency. In addition, the energy cost for pumps increases since the pump must work harder to overcome the increased pressure resistance through the PHE.

Differential pressure average for a PHE equals 2-4 psi when equipped with new or refurbished plates;

Service should be scheduled when the differential pressure increases up to 7-10 psi.

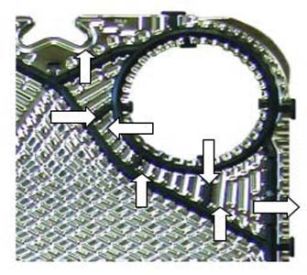

Fouled Plates Requiring Service or Replacement

What Causes Plate & Frame Heat Exchangers To Leak Internally?

- Higher pressure side will leak into the lower pressure side, if a plate develops a pin hole or crack;

- Over time the plates can crack since they are continuously flexing, this is often referred to as a “pop can effect” - continually bending the can back and forth in the same area will break it apart;

- Cross contamination is preventable when “double walled” designed plates are used with potable water.

*Municipal codes verify from region to region with most new construction by-laws requiring this safety measure

Damaged Plates

What Causes Plate & Frame Heat Exchangers To Leak Externally?

- Rubber gaskets installed on each plate create a seal, when gaskets become worn or damaged

- As the PHE ages the gaskets can dry out, lose their elasticity and become brittle

- Operating temperatures, pressures and exposure to process fluids can all reduce the life of a gasket

- Spiking or water hammer can force a gasket out of the plate groove

- Overheating can melt the rubber and cause the gasket to become brittle and crack

- Over tightening the groove the gasket sits in can become deformed. When this occurs the gasket will not sit flat and pushes outwards, (.4)mm thick gaskets are very susceptible to this issue

- Plates not installed correctly in a honeycomb pattern

The life span of a gasket in a cooling application is 10-15 years and for a heating application 8-10 years. Gaskets exposed to steam will typically wear quicker than if exposed to boiler water. PHE’s used strictly for seasonal heating will often leak during the first month of startup and seal after a few weeks as the gaskets expand.

When plates are installed correctly they will form a honeycomb pattern and if glue-less gaskets such as clip or ball are used, the tabs will be aligned.