VICARB plate heat exchanger gaskets

VICARB plate heat exchanger gaskets

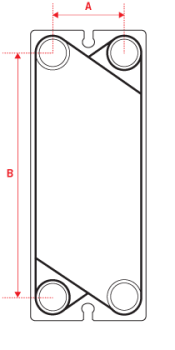

| Model Frame type |

V4 MAT/MST |

V4 DW MAT/MST |

V8 MAT/MST |

V13 MAT/MST |

V13 DW MAT/MST |

| A = mm | 62 | 62 | 100 | 130 | 130 |

| B = mm | 430 | 430 | 533 | 625 | 625 |

| Model Frame type |

V20 SAT/SST |

V20 DW SAT/SST |

V28 SAT/SST |

V45 SAT/SST |

V45 DW SAT/SST |

| A = mm | 130 | 130 | 234 | 234 | 234 |

| B = mm | 875 | 875 | 882 | 1302 | 1302 |

| Model Frame type |

V55 SAT/SST |

V60 SAT/SST |

V60 DW SAT/SST |

V85 SAT/SST |

V100 SAT/SST |

| A = mm | 330 | 540 | 540 | 380 | 310 |

| B = mm | 1133 | 1280 | 1280 | 1475 | 2000 |

| Model Frame type |

V110 SAT/SST |

V120 SAT/SST |

V130 SAT/SST |

V170 SAT/SST |

V180 SAT/SST |

| A = mm | 600 | 620 | 480 | 700 | 550 |

| B = mm | 1320 | 1589 | 1650 | 1650 | 2135 |

| Model Frame type |

V260 SAT/SST |

||||

| A = mm | 700 | ||||

| B = mm | 2492 | ||||