TRANTER Gaskets

TRANTER Gaskets

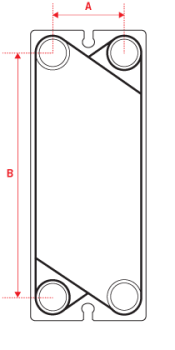

| Model | GC-12 GCD-012 |

GC-30 GCD-030 |

GC-48 GCD-048 |

GC-50 GCD-050 |

GC-26 GCP-026 |

GC-28 GCP-028 |

| A = mm | 60 | 100 | 135 | 226 | 65 | |

| B = mm | 357 | 555 | 590 | 779 | 675 | |

| Model | GC-51 GCP-051 |

GC-60 GCP-060 |

GX-7 GXD-007 |

UFX-12 GX-12 GXD-012 |

UFX-18 GX-18 GXD-018 |

UFX-26 GX-26 GXD-026 |

| A = mm | 300 | 420 | 60 | 135 | 135 | 226 |

| B = mm | 1143 | 910 | 640 | 592 | 822 | 779 |

| Model | UFX-42 GX42 GXD-042 |

UFX-51 GX-51 GXD-051 |

UFX-60 GX-60 GXD-060 |

UFX-64 GX-64 GXD-064 |

UFX-85 GX-85 GXD-085 |

UFX-91 GX-91 GXD-091 |

| A = mm | 226 | 300 | 420 | 285 | 570 | 285 |

| B = mm | 1189 | 1143 | 910 | 1320 | 1140 | 1800 |

| Model | UFX-100 GX-100 GXD-100 |

UFX-118 GX-118 GXD-118 |

UFX-140 GX-140 GXD-140 |

UFX-145 GX-145 GXD-145 |

UFX-180 GX-180 GDX-180 |

UFX-205 GX-205 GXD-205 |

| A = mm | 420 | 285 | 420 | 570 | 420 | 570 |

| B = mm | 1490 | 2280 | 2070 | 1720 | 2650 | 2300 |

| Model | 06T/UX-06T UXP-60 |

UX-01 UXP-010 |

UX-05 UXP-005 |

UX-10 UXP-100 |

11T UXP-110 |

UX-20 UXP-200 |

| A = mm | 114 | 114 | 260 | |||

| B = mm | 535 | 535 | 1100 | |||

| Model | UX-40 UXP-400 |

UX-80 | UX-81 UXP-801 |

UX-83 UXP-802 |

UX-90 UXP-900 |

|

| A = mm | 360 | 630 | 630 | 600 | ||

| B = mm | 1520 | 1860 | 1860 | 1868 | ||

| Model | S3 GFP-030 |

S8 GFP-080 |

TW-05 GFP-057 |

TW-10 GFP-097 |

TW-18 GFP-187 |

|

| A = mm | 380 | 380 | 380 | |||

| B = mm | 1053 | 1503 | 2473 |