KAPP & ARSOPI Gaskets

KAPP & ARSOPI Gaskets

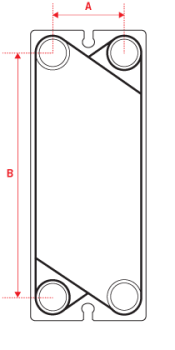

| Model | FH 00 | FH 01 | FH 10 FH 11 / 22 |

FH 20 FH 21 / 22 |

FH 30 FH 31 / 32 |

FH 40 FH 41 / 42 |

| A = mm | 160 | 300 | 390 | 680 | 610 | 760 |

| B = mm | 331 | 842 | 1140 | 1520 | 1891.5 | 2135 |

| Model | FH 80 | FH 90 UX 91 / 92 |

FH 100 102-103-104 |

FHE 11 | FHE 15 | FHS 40 FHS 43 / 45 |

| A = mm | 1450 | 1570 | 760 | 550 | 805 | |

| B = mm | 2829 | 3640 + | 2100 | 1445 | 2165 | |

| Model | FHS 41/ 44 | FHS 70 SX 71 / 74 |

FHR 00 FHR 01 / 02 |

FHR 10 FHR 13 / 14 |

FHR 30 FHR 31 / 32 |

FHR 70 FHR 71 / 72 |

| A = mm | 805 | 1070 | 242 | 460 | 660 | 900 |

| B = mm | 2165 | 2692 | 488 | 1212 | 1902 | 2434 + |

| Model | FHL 00 FHL 01 / 02 |

FHL 10 FHL 11 / 12 |

FHL 20 FHL 21 / 22 |

FHL 30 FHL 31 / 32 |

FHL 40 FHL 41 / 42 |

FHL 50 FHL 51 / 52 |

| A = mm | 350 | 410 | 700 | 650 | 800 | 810 |

| B = mm | 860 | 1084 | 1571 | 1540 | 2075 | 1936 |