Funke Gaskets

Funke Gaskets

| frame / pressure rating |

max. pressure range bar |

max. number of plates |

surface/ plate m2 |

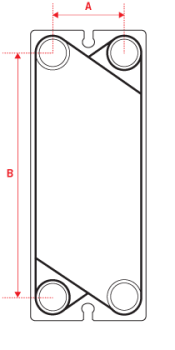

A mm |

B mm |

C mm |

D mm |

E mm |

L2 mm |

PP mm |

connections | max surface m2 |

| FP 04 FP 08 FP 14 FP 20 |

16 16 16 16 |

125 150 200 200 |

0,04 0,08 0,14 0,20 |

460 800 837 1066 |

160 160 310 310 |

336 675 590 819 |

65 65 135 135 |

85 85 132 132 |

150-600 150-600 250-1000 250-1000 |

pcs.x2,4 pcs.x2,4 pcs.x2,4 pcs.x2,4 |

1" 1" 2" 2" |

5 12 28 40 |

| FP 05 FP 09 FP-DW 05 |

25 25 16 |

150 150 150 |

0,04 0,08 0,04 |

532 827 532 |

200 200 200 |

381 676 381 |

70 70 70 |

45 45 45 |

250-1000 250-1000 250-1000 |

pcs.x2,7 pcs.x2,7 pcs.x2,9 |

1" 1" 1" |

6 12 6 |

| FP 10 FP 16 FP 22 FP-DW 16 |

25 25 25 25 |

200 200 200 200 |

0,10 |

733 933 1182 933 |

310 310 310 310 |

494 694 894 694 |

126 126 126 126 |

128 128 128 128 |

250-1000 |

pcs.x2,9 pcs.x2,9 pcs.x2,9 pcs.x3,1 |

2" |

20 30 45 30 |

| FP 19 FP-DW 19 |

16 |

500 |

0,19 |

1080 |

440 |

650 |

202 |

200 |

500-2500 |

pcs.x3,1 |

DIN 80 |

100 |

|

FP 205 |

25 25 25 25 25 |

500 500 500 500 500 |

0.21 |

1160 1332 1579 1826 2320 |

480 480 480 480 480 |

719 894 1141 1388 894 |

225 225 225 225 225 |

204 204 204 204 204 |

500-3000 |

pcs.x3,1 pcs.x3,1 pcs.x3,1 pcs.x3,1 pcs.x3,1 |

DIN 100 |

105 150 200 250 350 |

|

FP-DW 205 |

16 16 16 25 |

500 500 500 250 |

0.21 |

1160 1332 1826 2320 |

480 480 480 480 |

719 894 1388 894 |

225 225 225 225 |

204 204 204 204 |

500-3000 |

pcs.x3,3 pcs.x3,3 pcs.x3,3 pcs.x3,1 |

DIN 100 |

105 200 250 200 |

|

FP 41 |

25 25 25 16 |

700 700 700 700 |

0,40 |

1470 1835 2200 2200 |

620 620 620 620 |

941 1306 1671 2157 |

290 290 290 290 |

225 225 225 225 |

500-4000 |

pcs.x3,1 pcs.x3,1 pcs.x3,1 pcs.x3,1 |

DIN 150 |

280 420 560 560 |

|

FP 42 |

25 25 25 25 |

750 750 750 750 |

0,40 |

1470 1835 2200 2687 |

620 620 620 620 |

941 1306 1671 2157 |

290 290 290 290 |

225 225 225 225 |

500-4000 |

pcs.x3,1 pcs.x3,1 pcs.x3,1 pcs.x3,1 |

DIN 150 |

315 450 600 840 |

| FP 405 FP 70 FP 100 FP 130 FP-DW 100 |

25 25 25 25 16 |

700 700 700 700 700 |

0.41 |

1380 1740 2100 2460 2100 |

760 760 760 760 760 |

770 1130 1490 1850 1490 |

395 395 395 395 395 |

285 285 285 285 285 |

500-4000 |

pcs.x3,1 pcs.x3,1 pcs.x3,1 pcs.x3,1 pcs.x3,3 |

DIN 200 |

300 355 700 910 700 |

|

FP 81 |

25 25 25 25 |

800 800 800 800 |

0,80 |

1930 2320 2710 3100 |

980 980 980 980 |

1100 1490 1879 2267 |

480 480 480 480 |

365 365 365 365 |

1780-5280 |

pcs.x3,8 pcs.x3,8 pcs.x3,8 pcs.x3,8 |

DIN 300 |

640 960 1280 1520 |

|

FP 150 |

25 25 25 25 |

800 800 800 800 |

1,50 |

2500 2855 3211 3567 |

1370 1370 1370 1370 |

1466 1822 2178 2534 |

672 672 672 672 |

480 480 480 480 |

1980-5980 |

pcs.x4,1 pcs.x4,1 pcs.x4,1 pcs.x4,1 |

DIN 500 |

1600 1600 2000 2400 |

FP gasketed / bolted PHE (standard design) ? FP-DW safety PHE (double-wall plate design) ? FP-SW semi welded PHE (welded cassettes)

More types and sizes on request ? Technical changes reserved ? pcs. = number of plates